CTMe45 4" x 5" Downspout and Elbow Roll Former

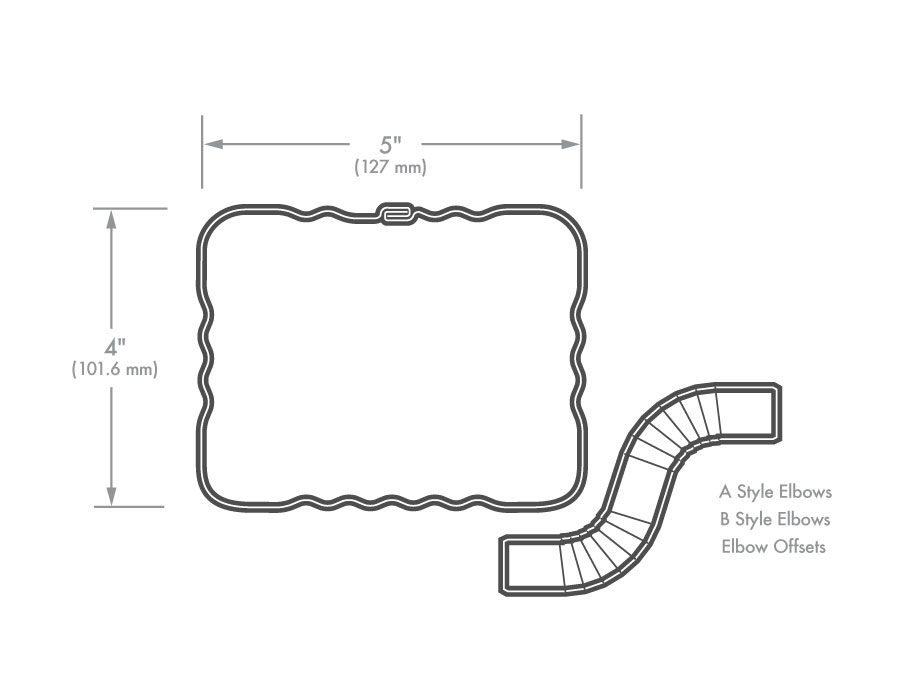

The CTMe45 downspout and elbow roll former offers a complete package for producing high volumes of 4×5” (76.2 X 101.6mm) downspout and elbow products. These machines also have the ability to bend elbow offsets which allows the production of many custom shapes in seamless pieces.

Get A Quote

Get A Brochure

Watch In Action

Watch In Action

Watch In Action

Detailed Product Information

4" x 5" Downspout and Elbow Profile

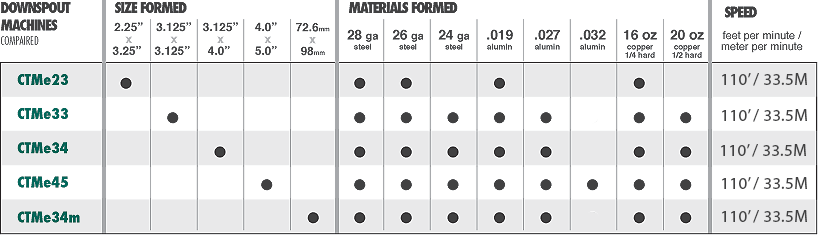

- Jobsite manufactures other downspout and elbow roll formers including:

- CTMe23 – 2×3″ (50.8 X 76.2mm) – Corrugated & Smooth

- CTMe33 – 3×3″ (76.2 x 76.2mm) – Corrugated

- CTMe34 – 3×4” (76.2 x 101.6mm) – Corrugated

- CTMe45 – 4×5” (101.6 X 127mm) – Corrugated

- CTMe34m – Metric 74.5 x 100mm

- RTMe3 – 3” (76.2mm) Round

- RTMe4 – 4” (101.6mm) Round

- PTMe23 – 2 x 3″ Smooth

- PTMe34 – 3 x4″ Smooth

Speed & Efficiency

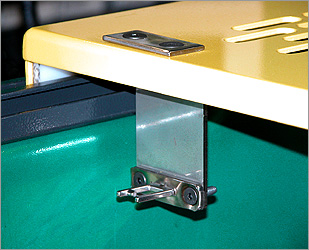

The machines can produce downspout at up to 85′ (25.9m) per minute and from .019 aluminum bend one “A” style elbow every 4 seconds. This yields up to 600 sticks 10′ long or up to 837 elbows in an hour. For efficiency, the elbow bending unit and crimper unit swing in and out to allow automatic crimping of straight pipe. Change overs just take minutes!

Range of Materials

Like always Jobsite equipment is able to run a large range of materials. The CTMe Series can run 24 to 28 gauge steel, .019″ to .032″ aluminum and 16 to 20 oz half hard copper.

Control and Accuracy

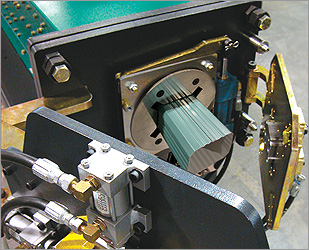

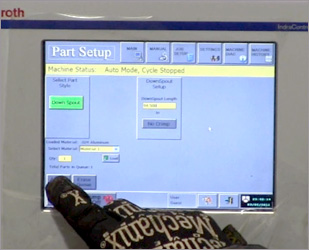

The CTMe Series machines are driven by an electric servo drive which is controlled by a PLC. This state-of-the-art technology allows the user to easily program, via touch screen control, 1 piece to 10,000 pieces at lengths from 3” and up within an 1/32” (0.8mm) accuracy.

Safety

Each machine comes equipped with sliding safety covers which will disengage the machine when opened. Also, emergency stop switches are located at each end.

Durability

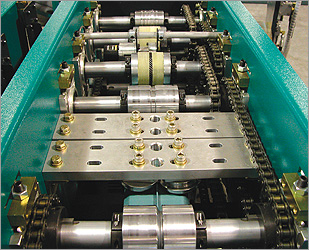

For long life, the machines are engineered with the highest structural integrity and all the forming rollers are hard chrome plated. The innovatively designed urethane drive rollers are easily replaceable.

Features

- Bosch touch screen controller capable of programming 1 to 10,000 pieces at lengths from 3” (7.6cm) to 100’ (3048cm) within an 1/32” accuracy

- Forms downspout at variable speeds up to 85 feet (25.9m) per minute. Can bend 800 aluminum “A” style elbows an hour at 75° with 6 crimps

- Will run 35ksi 24 to 28 gauge steel, 0.019 to 0.032 aluminum, 16 oz. and 20 oz. ½ hard copper

- The electric servo drive verses hydraulic (hard start and stop) drive, allows for a soft start and stop reducing wear and tear and extending the life of the machine

- Hard Chrome Plated Rollers and Shafts

- Innovatively designed Urethane Drive Rollers designed for long life and easy replacement

- Safety interlocks on all sliding covers and emergency stop buttons on both ends of the machine

- Includes 6000lb 12” Single Reel Power De-coiler

- 24 Month Limited Warranty on Jobsite Manufactured Parts, excluding wearable parts, (urethane rollers, shear parts) and Manufacturer's Warranty on purchased parts

CTMe45 Specifications

- Length: 336” (853.44cm)

- Width : 52” (132.08cm)

- Height: 54” (137.16cm)

- Weight: 8000 lbs (3629 kg)

- Main Power: 380/460V, 3 PH, 50/60Hz, 30 Amp

- Linear Drive Power: Electric servo

- Drive: Forming rollers driven by sprockets, chains and gears

- Hydraulic Power: 10 Hp electric motor

- Coil Width: 17.562” (446.07mm)

Options

- Internet Connectable Diagnostics thru controller for quick troubleshooting

- Dual Reel Power Decoiler

- Run Out Stands

- Overseas Wiring