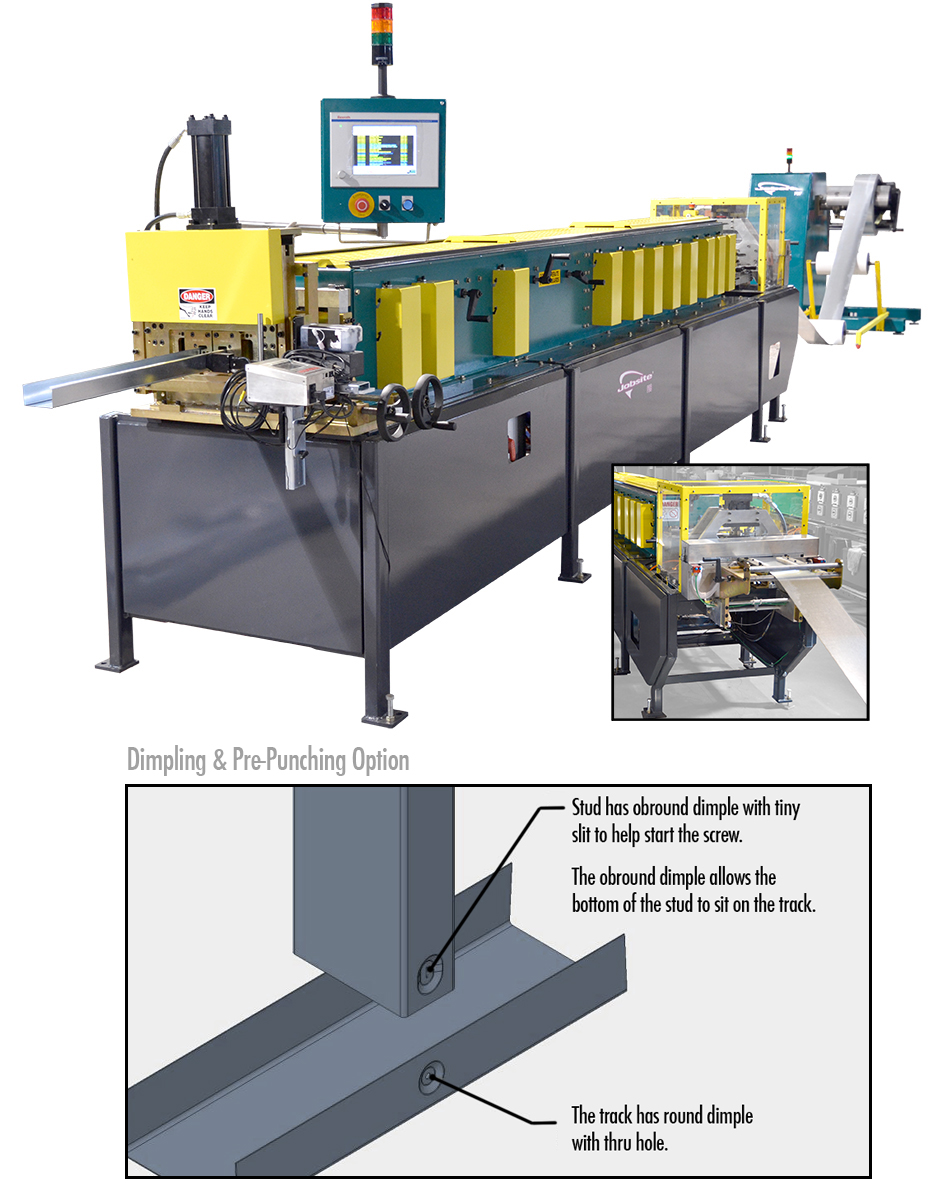

PS800 Steel Stud Machine - 12 Gauge

The Jobsite PS800 12 gauge steel stud machine roll forms steel stud and track members for use in wall, floor and truss framing. The 12 gauge machine produces stud & track members from 3 5/8″ (92.1mm) to 8″ (203.2mm) widths and 20 gauge (0.034) through 12 gauge (0.105). This machine has had all the internal parts, shear and punch system upgraded to handle the thicker 12 gauge material.

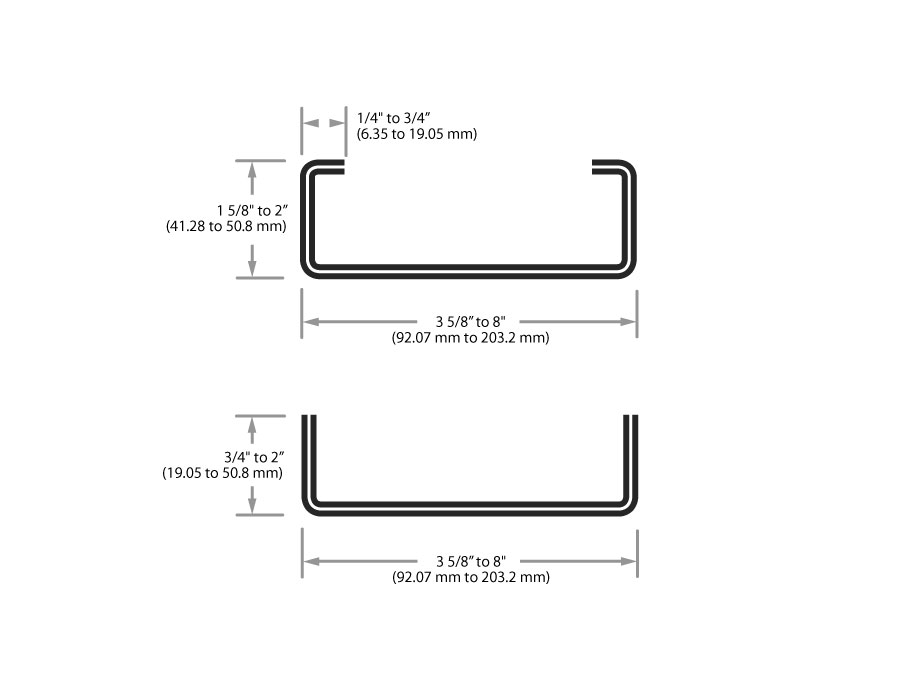

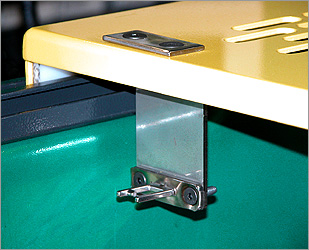

Dimpling & Pre-Punching add-on options:

- Heavy Duty Dimpling & Pre-Punching (20 to 12 gauge)

Dimpling & Pre-Punching increases assembly productivity and eases screw positioning on 3 5/8″ (92.1mm), 6″ (152.4mm) and 8″ (203.2mm) web widths and 1 5/8″ (41.3mm) and 2 1/2″ (63.5mm) flange widths. Also the obround dimple ensures proper stud placement on the track.

Detailed Product Information

Profile

The standard machine roll forms the profile sizes shown. Profile options and other steel framing equipment is available.

Speed & Efficiency

Range of Materials

Control and Accuracy

Safety

Durability

Features

- Bosch Rexroth controls and drive for accuracy and history of excellent reliability

- Servo driven punch provides close tolerance accuracy and none stop punching for increased production, with interchangeable tooling for different hole sizes and shapes. Maximum size is 1 1/2″ (38.1mm) X 3 1/2″ (88.9mm) obround

- Includes 3 Stud and Track kits: 3 5/8″ (92.07mm), 6″ (152.4mm), 8″ (203.2mm) sizes

- Hydraulic shear with quick change dies

- Nitride Hardened rollers designed for long life for running galvanized steel

- Material oiler / mister to aid in keeping the rollers clean when running galvanized material

- Safety interlocks on all sliding covers that meet OSHA requirements

- Emergency stop buttons on both ends of the machine

- Safety stack lights on machine and decoiler indicates equipment in operation

- 24 month limited warranty on Jobsite manufactured parts, excluding wearable parts, (shear/punch parts) and manufactures warranty on purchased parts

PS 800 Steel Stud Machine 12 Gauge Specifications

- Length: 245″ (6.22 m)

- Length with options: 305” (7.75m)

- Width: 44″ (1.12 m)

- Height: 65″ (1.65 m)

- Weight: 7800 Pounds (3538 kg)

- Equipment Power Requirement: 380/460V, 3ph/50/60Hz, 70 Amp

- Main Servo Drive: 203.5 in lbs/ 23.0 NM continuous torque (x3 peak)

- Punch Servo Drive: 70.8 in lbs/8.0 NM continuous torque (x3 peak)

Options

- Heavy Duty Dimpling / Pre-Punching for precision screw positioning in 18, 16, 14, 12 gauge material (3 1/2″, 6″ and 8″ stud and track only)

- Internet connectable diagnostics available to aid in trouble shooting

- Vertex BD Framing Software

- Stand-Alone Crane System

- Semi-Auto Manual Unload Table for stud and track roll formers

- Any material size Imperial or Metric

- Customize stud & track kits sizes from 3 5/8” to 8” or metric sizes

- 6,000 lb Single Reel De-coiler 17”- 24” (0.430m – 0.610m)

- Dual Reel De-coiler

- Ink Marking System

- Containerized machine