Metal Laser Cutting

Metal Laser Cutting technology involves CAD or 3D Solid Works drawings integraded into the laser control. The Laser, CNC driven, directs the output of a high-power laser at the material to be cut. The material then either melts, burns or vaporizes away leaving an edge with a high-quality surface finish.

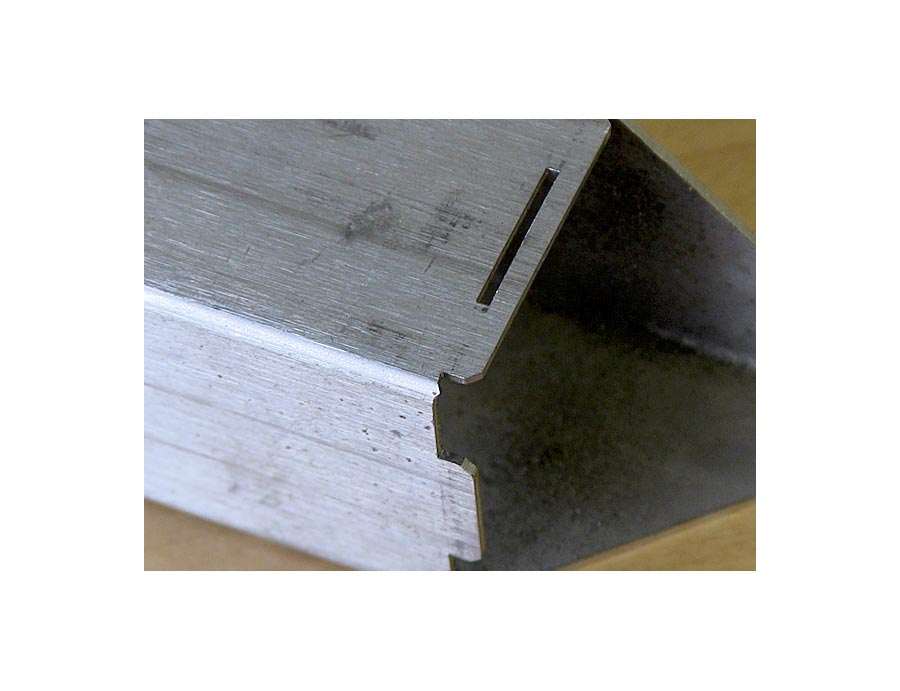

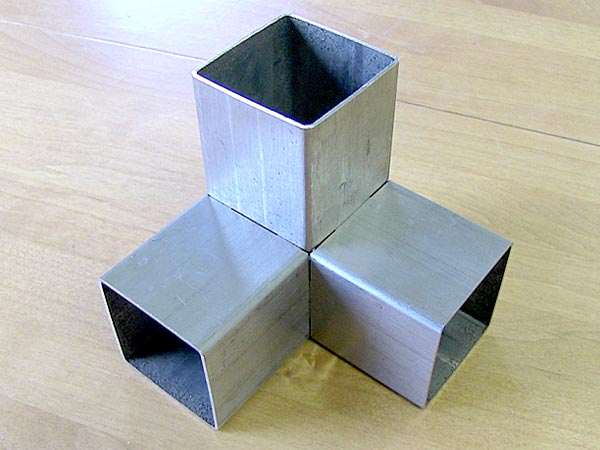

Armed with two state-of-the-art lasers (including a new Tube Laser Cutting Amada FOM2) Jobsite can cut one or many custom pieces out of steel, stainless steel, aluminum, copper, brass, titanium and tool steel with a tolerance of +/- 0.007. The Engineering department can design a part and send the resulting CAD file directly to one of Jobsite’s laser cutters, which is then batched and cut. Each laser is assisted by a shifting table and rotary clamps which increases the potential cutting area and allows for notching, coping, tabbing and snap fitting.

Metal Laser Cutting, Welding & Marking Equipment

Models:

- Amada FOM2 – 3 axis laser with sheet processing and rotary index – capable of cutting angle and tube.

- Mitsubishi Model 3015 HC – 3 axis metal laser cutting center.

- Control-Laser Engraving & Marking System