Precision Wire EDM Cutting

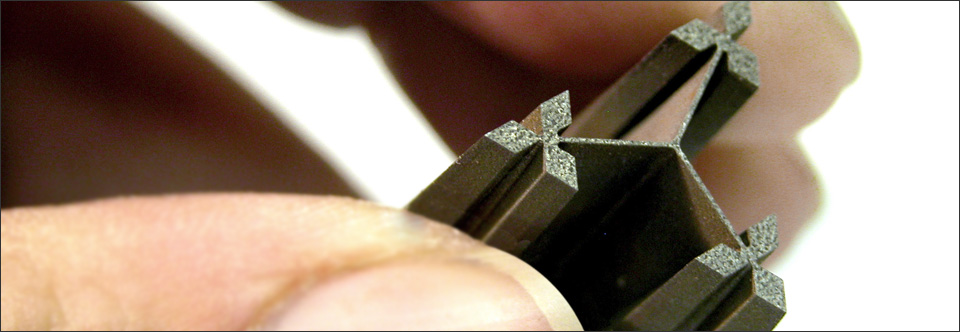

Precision Wire EDM cutting, also know as electrical discharge machining, is a metal cutting technology able to cut steel with amazing precision and accuracy using an electrically energized thin wire. It works by creating an electrical discharge between the wire or electrode, & the workpiece. As the spark jumps across the gap, material is removed from both the workpiece & the electrode. Due to the inherent properties of the process, wire EDM can easily machine complex parts and precision components out of hard conductive materials.

Precision wire EDM cutting is used for simple or complex shapes including, intricate openings and sharp inside corners for parts like gears, robot parts, nozzles, punch and die tooling, stripper plates, mold components and much more. Normally precision wire EDM cutting tolerances are +/-.0002 however cutting smaller tolerances is possible.

Precision Wire EDM Equipment

Wire EDM Equipment

- Mitsubushi FA20 Wire EDM – Max workpiece dimension (41.3″ W), (31.4″ D), (11.6″ H), max weight 3,300 LBS, machining range (19.6″ X), (13.7″ Y), (11.8′ Z).

Materials Possible

Material thicknesses can be cut from only a few thousandths of an inch to several inches applied to:

- Aluminum

- Stainless Steel

- Copper

- Steel

- Brass

- Titanium

- Sterling Silver

- Spring Steel

- Bronze

- Super alloys

- Very hard and difficult to machine metals