What is EDM machining? How does it work?

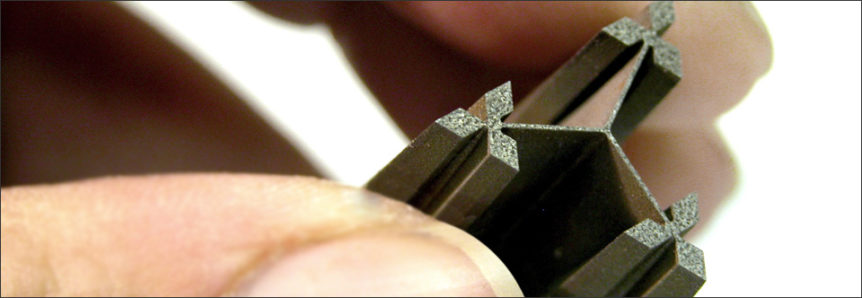

ELECTRICAL DISCHARGE MACHINING (EDM) is a metal cutting technology able cut steel with amazing precision and accuracy. This is accomplished with a system comprising two major components: a machine tool and a power supply. The machine tool holds a shaped electrode which advances into the workpiece and produces a shaped cavity. The power supply produces a high frequency series of electrical spark discharges between the electrode and the workpiece, which removes metal from the workpiece by thermal erosion or vaporization.

The basic components of an EDM system are illustrated to the right. The workpiece is mounted on the table of the machine tool and the electrode is attached to the ram of the machine. A DC servo unit or hydraulic cylinder moves the ram (and electrode) in a vertical motion and maintains proper position of the electrode in relation to the workpiece. The positioning is controlled automatically and with extreme accuracy by the servo system and power supply. During normal operation the electrode never touches the workpiece, but is separated by a small spark gap.

During operation, the ram moves the electrode toward the workpiece until the space between them is such that the voltage in the gap can ionize the dielectric fluid and allow an electrical discharge (spark) to pass from the electrode to the workpiece. These spark discharges are pulsed on and off at a high frequency cycle and can repeat 250,000 times per second. The spark discharge (arc) always travels the shortest distance across the narrowest gap to the nearest or highest point on the workpiece. The amount of material removed from the workpiece with each pulse is directly proportional to the energy it contains.

During operation, the ram moves the electrode toward the workpiece until the space between them is such that the voltage in the gap can ionize the dielectric fluid and allow an electrical discharge (spark) to pass from the electrode to the workpiece. These spark discharges are pulsed on and off at a high frequency cycle and can repeat 250,000 times per second. The spark discharge (arc) always travels the shortest distance across the narrowest gap to the nearest or highest point on the workpiece. The amount of material removed from the workpiece with each pulse is directly proportional to the energy it contains.

Each discharge melts or vaporizes a small area of the workpiece surface. This molten metal is then cooled in the dielectric fluid and solidifies into a small spherical particle (swarf) which is flushed away by pressure/motion of the dielectric. The impact of each pulse is confined to a very localized area, the location of which is determined by the form and position of the electrode.

Both the workpiece and electrode are submerged in a dielectric fluid which acts as an electrical insulator to help control the spark discharges. In EDM, the dielectric fluid also performs the function of a coolant medium and reduces the extremely high temperatures in the arc gap. More importantly, the dielectric fluid is pumped through the arc gap to flush away the eroded particles between the workpiece and the electrode. Proper flushing is critical to high metal removal rates and good machining conditions.

Because EDM erodes metal with electrical discharges instead of with chip machining cutting tools, the hardness of the workpiece does not determine whether or not a material can be machined by EDM. A relatively soft graphite or metallic electrode can easily machine hardened tool steels or tungsten carbide. This is one of the many attractive benefits of using the EDM process. Rather than machine a workpiece before heat treating, it can be EDMed afterward. This eliminates the risk of damage or

distortion which could scrap an expensive workpiece during heat treating.

The basic principles of wire-cut EDM are essentially the same as diesinking EDM described above. The major difference is that instead of using an electrode with a complex shape, in wire EDM the electrode is a simple wire, typically .006″ to .012″ diameter, which follows a horizontal path through the workpiece. Instead of using dielectric oil as in die-sinking EDM, wire EDM uses deionized water.